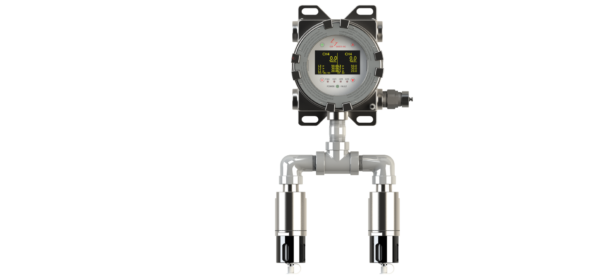

Combustible Gas Detectors

FAST AND RELAIBLE DETECTION

ESP Safety’s SIL-2 certified flammable gas detectors are reliable and smart detectors for every gas application in which critical protection is needed. Our gas detectors are configured to report alarms when the gas concentrations in the environment reach alarm level of the lower explosive limit (LEL) in the air.

We offer three different technologies for combustible gas detection:

Infrared (IR),

Catalytic bead,

Open path.