IPES IR3

Flame Detectors

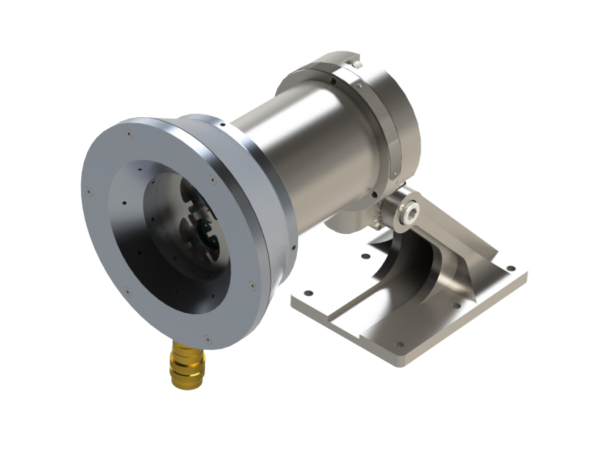

IPES IR3

- SIL 3 Certified

The multi-spectral infrared technology of ESP Safety’s IPES-IR3 Flame Detector provides the highest sensitivity in detecting flames within a wide field of view. IPES-IR3’s advanced detection algorithm ensures rapid flame recognition while virtually eliminating false alarms.

Alarms are sent only when ratios between three different IR wavelengths confirm that a flame is present in the field of view. IPES IR3 ignores false triggers from sources such as direct or indirect sunlight, arc welder flash, resistive heaters, fluorescent, halogen, and incandescent lights.

The built-in continuous self-check function will notify you if anything is obstructing the detector’s field of view or if there are circuit integrity problems. The unit comes standard with multiple outputs and you can choose to connect the detector via 4-20mA, RS485 or relays to your system for reliable communication.

For those applications where condensation may occur, an internal heater will activate to prevent any damage. And with power consumption less than 3W, ESP’s flame detector IPES IR3 assures low power costs.

The maximum area coverage along with SIL 3 rating makes IPES IR3 the best fit where reliability and performance are required. IPES IR3 has extended temperature range version -60 degrees Celsius to + 125 degrees Celsius for the most demanding industry applications.

The detector comes in both stainless steel and aluminum housing.

Multi-spectral IR detection

Low Power Consumption

Long Detection

5 Year Warranty

Electrical Specifications

Power Requirements: 24VDC nominal (18 to 32VDC range)

Power Consumption: 3W maximum 3VA

Signal Outputs: +4 to 20mA, Digital RS485 Modbus, Relays.

*All Relays Contact Rating 1 Amp@125VAC/30VDC

Factory Default Relays Settings:

•Fire Relay: Normally Open, Closed on Fire Detection, Non-Latching

•Fault Relay: Normally Closed, Open on Fault Detection, Non-Latching

Performance Specifications

Detection Response Time: 4.5 to 7 seconds

Detection Distance: Up to 211ft (65m) depending on detected fuel

Detection Field of View: Up to 90° (45° Left/Right of center)

Mechanical Specifications

Ingress Protection: IP66

Operating Temperature: ‐40°F to +185°F (‐40°C to 85°C)

Extended Operating Temperature: ‐76°F to +257°F (‐60°C to 125°C)

Storage Temperature: ‐76°F to +185°F (‐60°C to 85°C)

Humidity Range: 0 to 98% relative humidity (can withstand 100% condensing humidity for short periods of time)

Conduit Connection: Two (2) M20 X 1.5, adaptable to ¾” NPT

Enclosure Material: Stainless Steel (Grade 316) or Aluminum (coated)

Dimensions: 9.08″X 14.20″X 3.94″ (231mm X 361mm X 100mm) mounted with bracket

Weight: Stainless Steel 13.2lb (6.0kg), Aluminum 7.7lb (3.5kg)

- Drilling and production platforms

- Shipping tankers, freighters, and other vessels

- Fuel loading facilities

- Refineries, bulk terminals, and tank farms

- LNG/LPG processing and storage facilities

- Compressor stations and pipeline facilities

- Petrochemical, paint, and fertilizer plants

- Power plants and gas turbine facilities

- Transportation facilities (airports and subways)

- Oil and gas fired boilers / furnaces

ITES Test Lamp

Protective Visor

Magnetic Collar

Mounting Bracket

a tilt of up to +/-45deg in the vertical plane.